We have been making penetrant equipment for as long as our company has existed.

With EMCOL penetrant equipment you have the confidence that the units are built by the people that use them every day to test a wide variety of different components.

We base our design on a modular approach. This makes it relatively easy to add a new penetrant tank or a larger oven later down the road without having to purchase a completely new line.

Along with our standard units listed below we make completely bespoke equipment to suit your exact needs.

Penetrant & Emulsifier Tanks

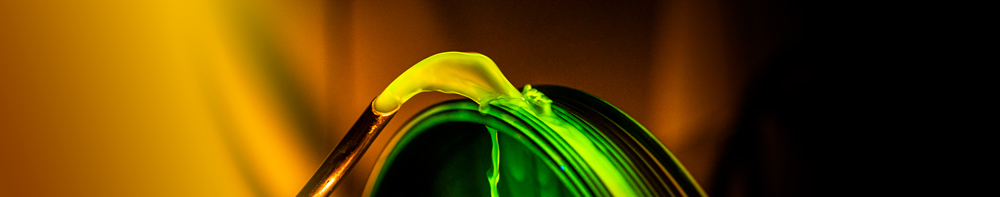

Fabricated from stainless steel our penetrant application tanks are designed to maximise the working area but minimise the fill volume so it doesn’t cost thousands of pounds to fill the tank. Supplied with a moveable built in drain shelf and removable contents label these tanks are ideal for large components or high volume basket work and can be fabricated with a working area in excess of 1200 x 1200mm.

EMCOL 3 Tank

The EMCOL 3 Tank is a cost effective three tank system for use with a separate oven and developer station. We can also manufacture any combinations and sizes of tanks to suit all purposes.

Features include:

- Stainless Steel Working Top

- Stainless Steel Lids

- Drop in tanks easy to empty/replace

- Slot in contents labels for each tank

- Removable drain shelves

- Matches EMCOL Drying ovens and Powder Storms

- Easy to keep clean

WS 1000 Wash Station

The WS 1000 is a sophisticated penetrant wash station incorporating pressure controls and gauges. Clean water weir wash, holding tank and waste conditioning unit. Ideal for pre and post removable fluorescent techniques.

Features include:

- Stainless Steel Welded Construction

- Large Size Nom 1200 x 800 Wash area

- Splash guards to rear and sides

- Solenoid valve operation for water supply and weir

- Pressure limiting valves for air and water

- Built in water heater to maintain temperature within 10°C-38°C

- Built in Digital Water Tempeature Gauge & Pressure Gauges

- Waste conditioning unit to hold non-emulsified penetrant

- Supplied with air water gun

Drying Ovens

We manufacture a range of drying ovens suitable for both Penetrant Process and drying after aqueous processes before penetrant inspection.

Features include:

- Stainless Steel Lined Interior

- Removable Shelves

- Digital Temperature Display and Control

- Settable Overtemperature Cut-Out

- Can be used for 120℃ and 70℃ operations (RRP58003 and Nadcap Requirements)

- Fan assisted hot air convection with outlet

- Range of sizes available

Dust Storm Developer cabinet

The PS 1000 is a microprocessor controlled dust storm cabinet suitable for application of dry powder developers as used in penetrant inspection.

Our most common unit in the range is the PS1000 (1000x1000x500mm) but we have made much larger units in the past in excess of 2000mm x 1000mm.

Features include:

- Microprocessor control

- Large Capacity Nom 1000 x 1000 x 500mm

- Easy Access - Top Loading - Lid supported by Gas Struts

- Internal light and viewing window

- Lid open alarm

- Shaped for minimal fill